Handling Cohesive Battery Materials With Ease

Metering cathode and anode materials in battery manufacturing can be a critical and precise process, and there are several potential complications that can arise if not properly managed. These complications can impact the quality, consistency, and efficiency of battery production. The unique characteristics of these materials, which can vary, often challenge accurate measurement, mixing, and transportation. Factors such as flowability, adhesion, and settling tendencies can lead to uneven distribution, affecting the performance and consistency of battery electrodes. Manufacturers must implement equipment to overcome these complications and ensure the reliable production of high-quality batteries.

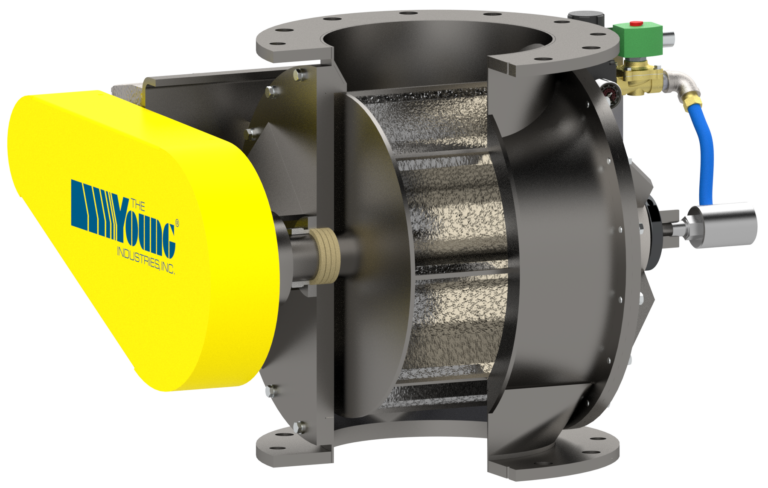

Model EV Rotary Valve

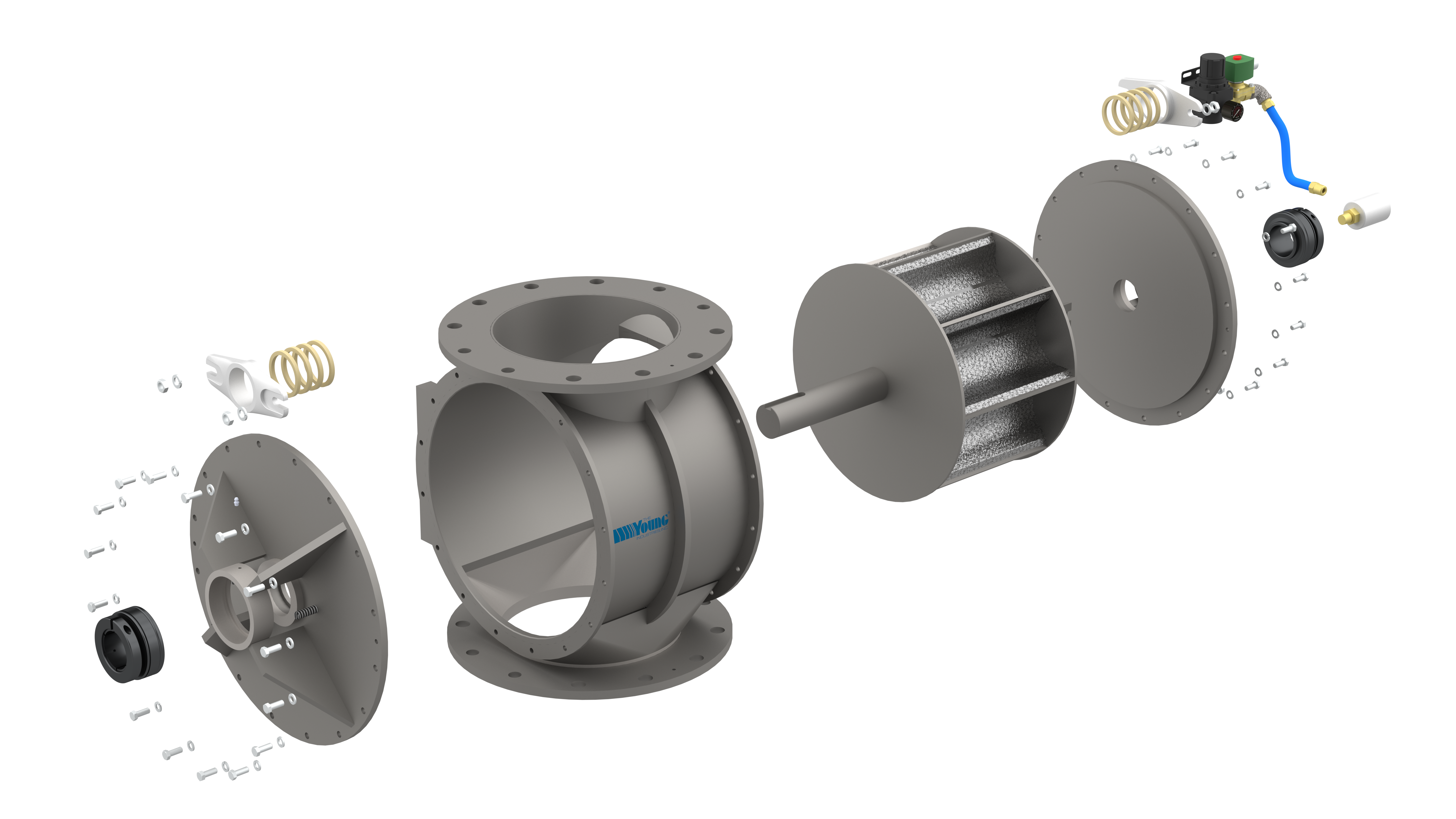

The Young Industries’ Model EV Rotary Valve has proven to be an effective way to meter cohesive battery materials into powder processes. We understand the difficulty of handling anode and cathode materials. For this reason, we have integrated our long-standing rugged rotary valve design with our aeration technology, TransFlow®, to develop the Model EV Valve. The rugged valve design works well in harsh and demanding environments. The TransFlow® technology aids in fluidizing the material in the pocket of the rotor both conditioning the material and reducing its ability to stick in the pocket. This enables a more consistent reliable flow into downstream processes. This combination has created a valve that can tackle the problematic handling of cohesive materials found in the manufacturing of anode and cathode battery recipes. The Model EV Rotary Valve is designed to handle material such as carbon black, graphite, nickel-based powders, lithium-based powders with ease.

Specifications

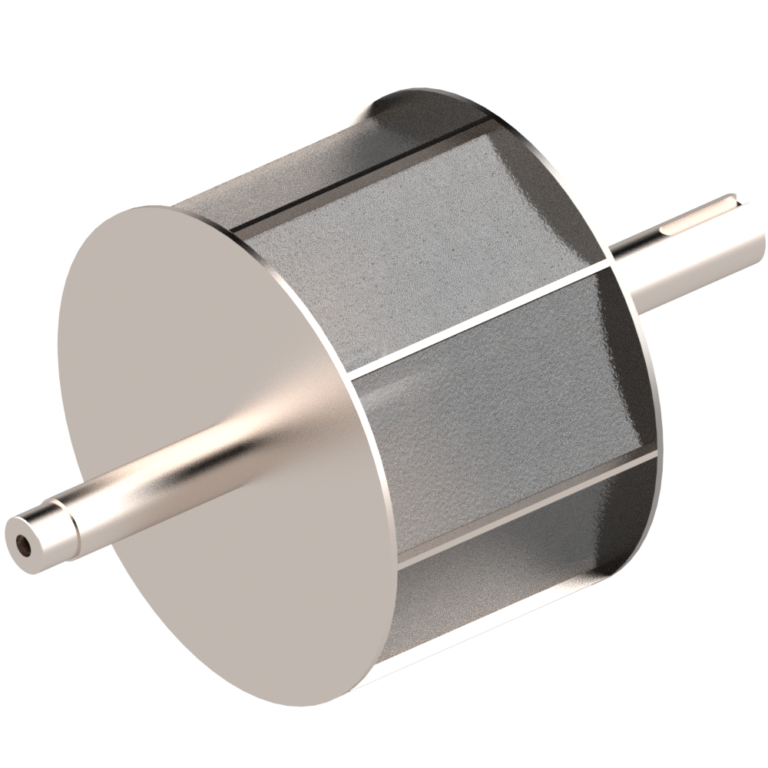

The Model “EV” Rotary Valve is used to effectively meter cohesive battery materials into powder processes. The key to this is our TransFlow® technology. This valve is unique as the pocket of the rotor is lined in TransFlow® which fluidizes the material. Low pressure compressed gas/air is supplied to the backside of our TransFlow® material which permeates the porous material and creates a non stick surface.

Our Model “EV” Rotary Valve can be used to meter carbon black, graphite, nickel-based powders, lithium-based powders with ease. However, this valve isn’t limited to these materials and can be used in the metering of other various cohesive or hard to handle materials that you may find in other industries.

- TransFlow® lined rotor for material fluidization and release.

- Heavy duty construction with 15 PSIG internal and differential pressure rating.

- Constructed of carbon steel or 300 series stainless steel.

- Standard design/operating temperature up to 250°F.

- Round, square, or custom inlet and discharge flanges.

- Outboard-mounted precision ball bearings.

- Packing gland provides a tight rotor shaft seal with four rings of PTFE impregnated Kevlar.

- End plates are piloted to assure concentricity of the housing so that tight internal clearances between rotor and housing is provided.

- Air flow controls for TransFlow®.

- All stainless steel control components.

- Motion speed switch.

- VFD inverter.

- Explosion proof electrical components.

- Teflon lantern ring with purge connection in the packing gland.

- High internal pressure designs up to 50 PSIG.

- High temperature designs up to 500°F.

- Roller chain drive with parallel shaft TEFC driven gearmotor is standard with explosion proof motors of any specified manufacturer available.

- Special packing materials of graphite, food grade PTFE, or as needed by process.

- Direct venting with vent installed in the housing.

- End plate purges.

- Rotor tips and edges can be beveled.

- End plate o-rings.

- Shrouded or open rotors with standard or filled pockets.

- Exterior painting and coatings to meet customer specifications.