Description

- Designed as a single feeder control system that can operate one complete feeder system including a refill valve

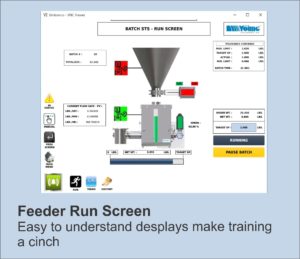

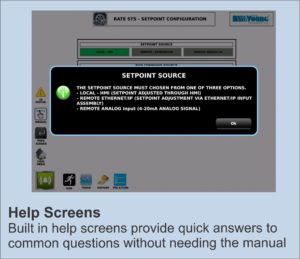

- It boasts a user-friendly color touch screen interface that is easy to understand and operate both locally or remotely. It’s built in help menus answers common questions without the need to find a manual

- It’s standard Ethernet IP communications allow it to integrate with other control systems. VNC capabilities make it easy to mirror the HMI to virtually any device connected to the same network using free VNC Software

- Its multi-level password protection allows the supervisor to limit access to setup screens

- The standard package is rated for use in an NEMA 4 environment

Optional Area Ratings

- NEMA 4X

- Class 1 Div. 1 (X-Purge)

- Class 1 Div. 2 (Z-Purge)

- Class 2 Div. 1 (X-Purge)

- Additional enclosures and control package designs are available

Control Panel Features

- 10.4″ Color Touch Screen with 800 x 600 Resolution

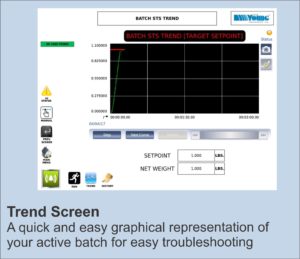

- SWIFT Seek Technology allows quick and accurate seek time when rate feed starts up or a set point change occurs

- Refill vector auto-adjusts motor speed based on historical motor speed at current gross weight.

- Auto-Tune feature for quick & Easy Setup

- Totalizer tracks total amount of material discharged since the last reset

- Built-In alarms for easy diagnostics and process monitoring

- Built in Help Screens provide quick answers to common questions without the need to read a manual

- Auto-Disturbance Detection senses a scale disturbance and within micro-seconds, it enters an open loop volumetric mode which adjusts the motor speed based on the hopper level and quickly recovers when the disturbance is no longer present

- Standard Hardware includes extra IO for remote monitoring and operation along with spare IO that can be custom configured for special applications

- Universal 24V Power Supply accepts 85V to 150V AC Current (other voltages available as options)

- Ambient Design Temperature 32º F (0º C) to 122º F (50º C)

- Auto Refill Cycle

- Multi-Language User Support Available

- Universal Motor Output Speed Reference will control DC Stepper Motors, or 3PH Motors

- Web server for easy setup and diagnostics using standard web browser

- Standard Communication protocol: Ethernet IP

- Optional communications available for Modbus/IP and Modbus RTU