NFPA Compliant Valves

Model HC & LH

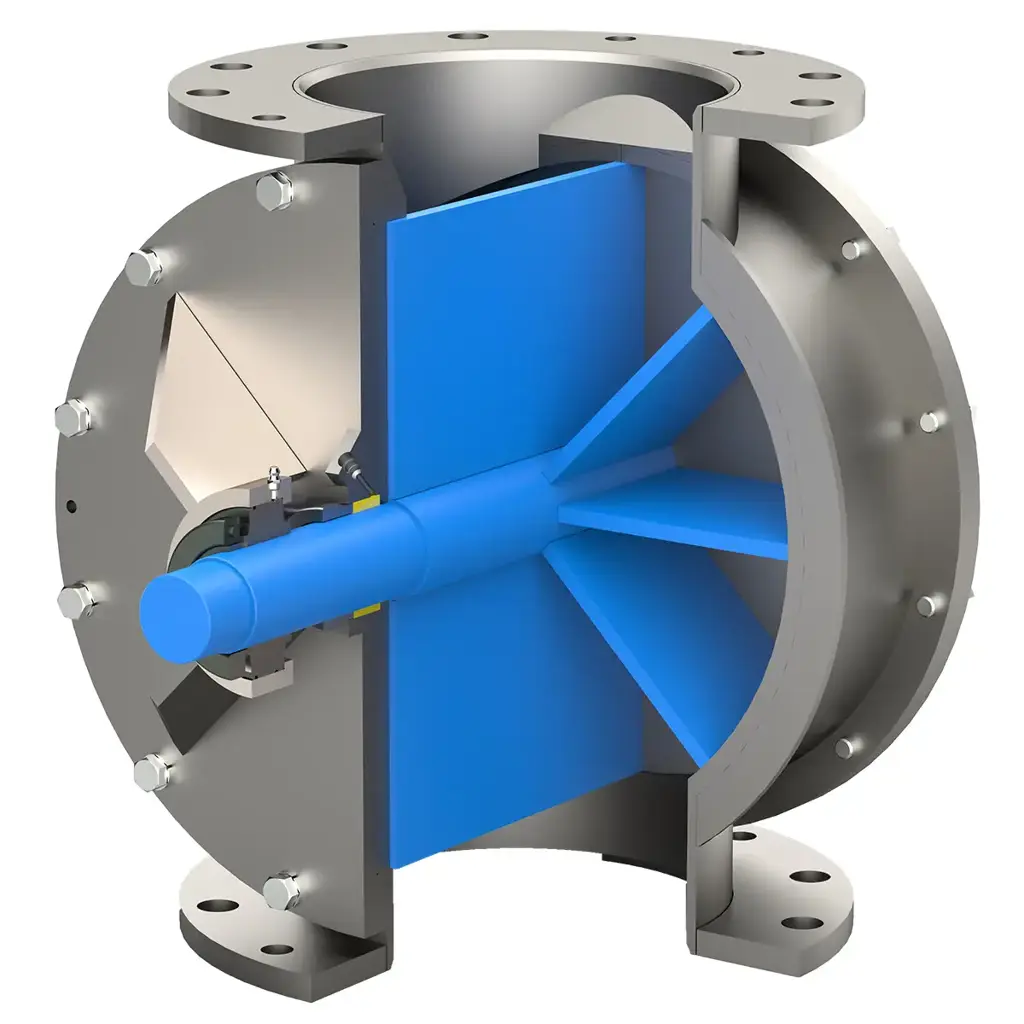

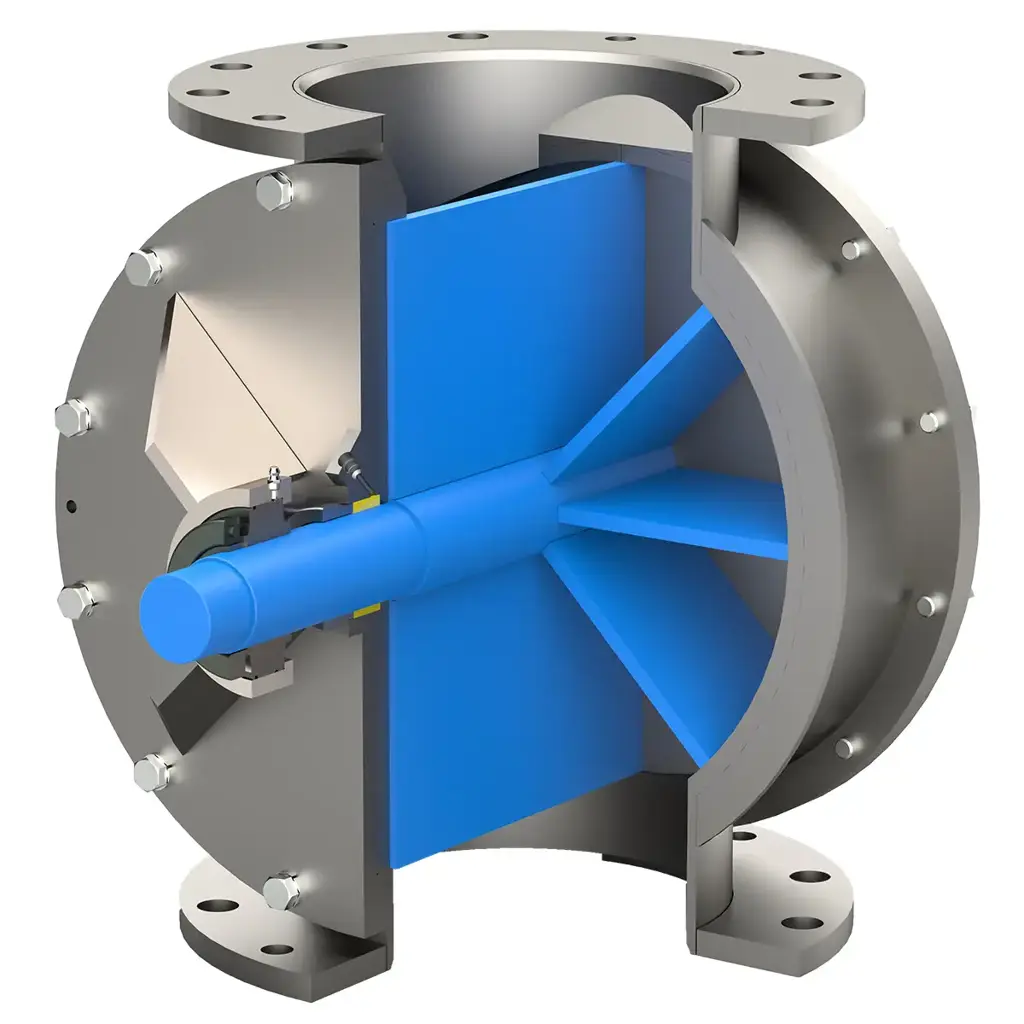

Young Industries manufactures NFPA-compliant close-clearance rotary valves tailored to your specific application. These valves act as critical safety devices, isolating deflagrations and protecting adjoining equipment through flame quenching.

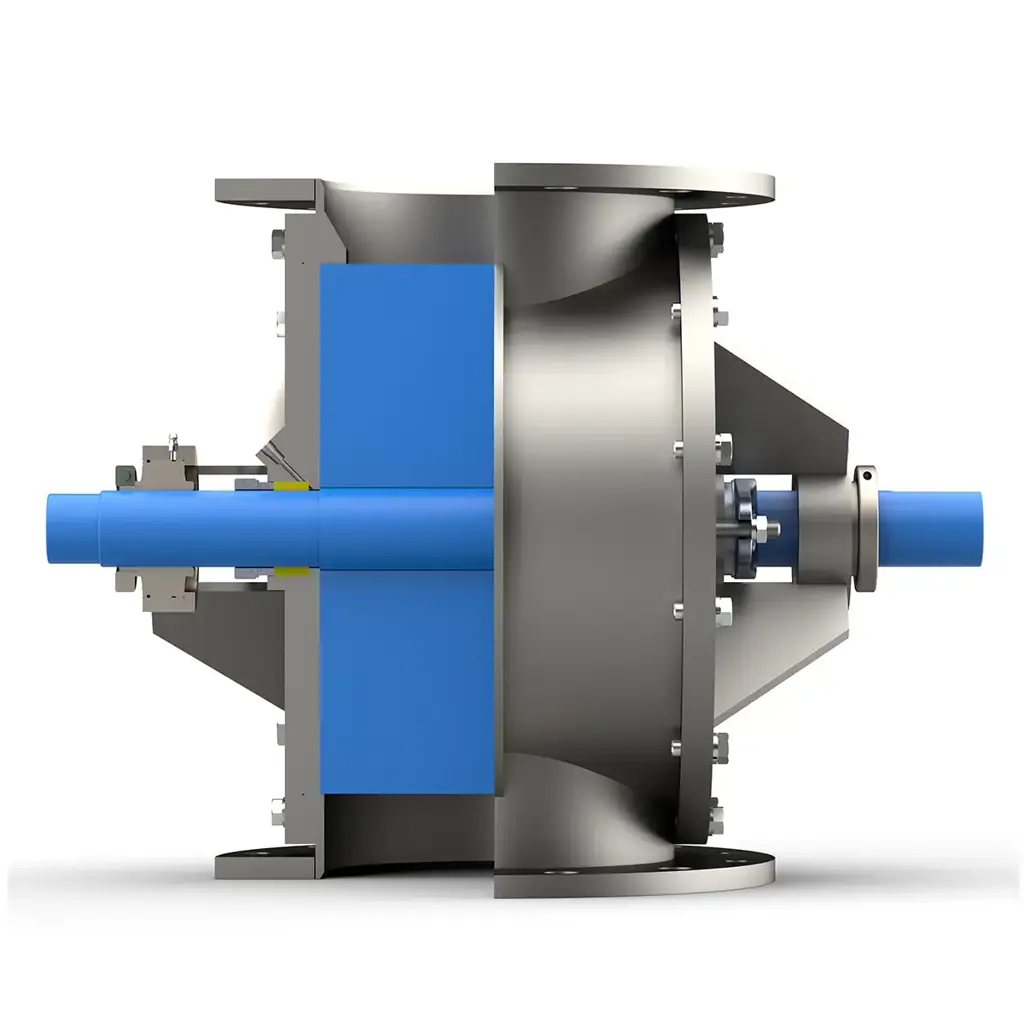

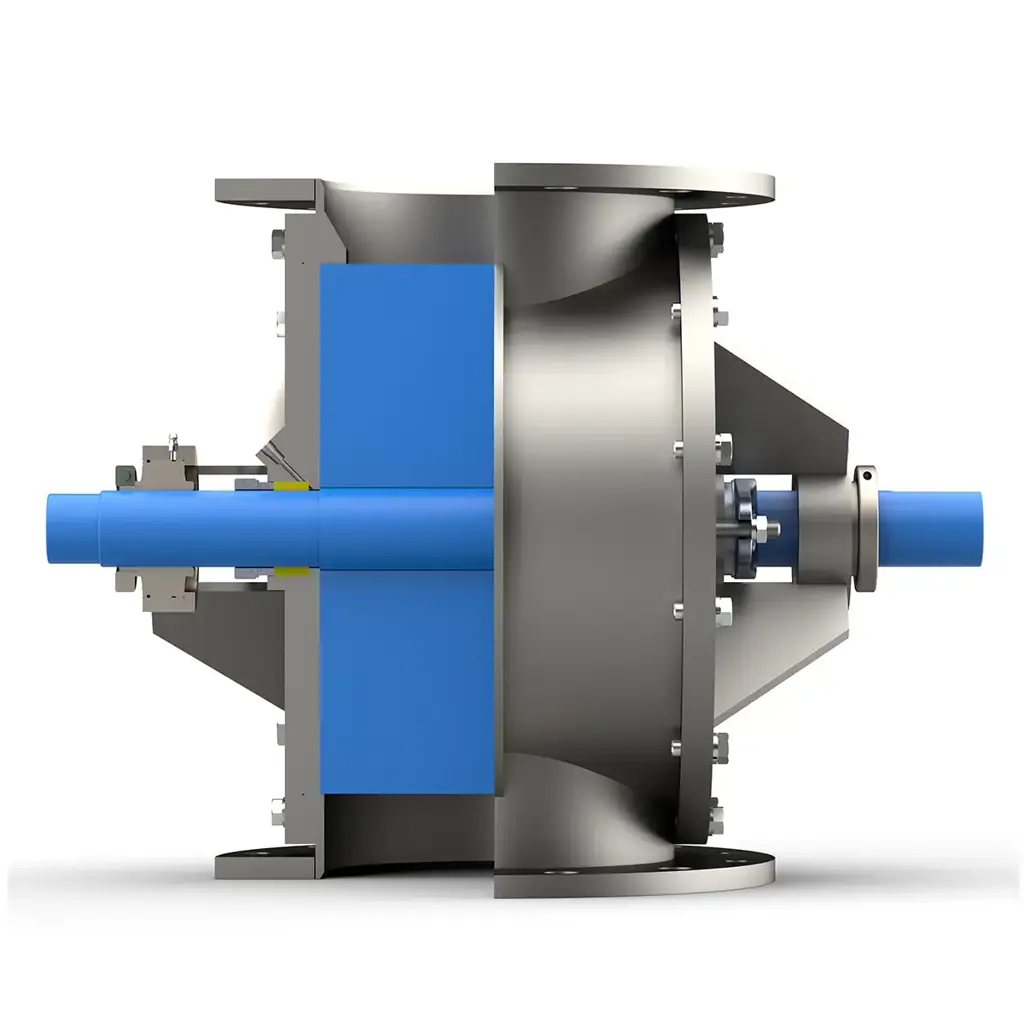

Our Model LH and Model HC Drop-Thru Rotary Valves are designed to handle a wide range of powders. When your application demands it, we can equip these valves with features to meet NFPA 69 standards for close-clearance rotary valves.

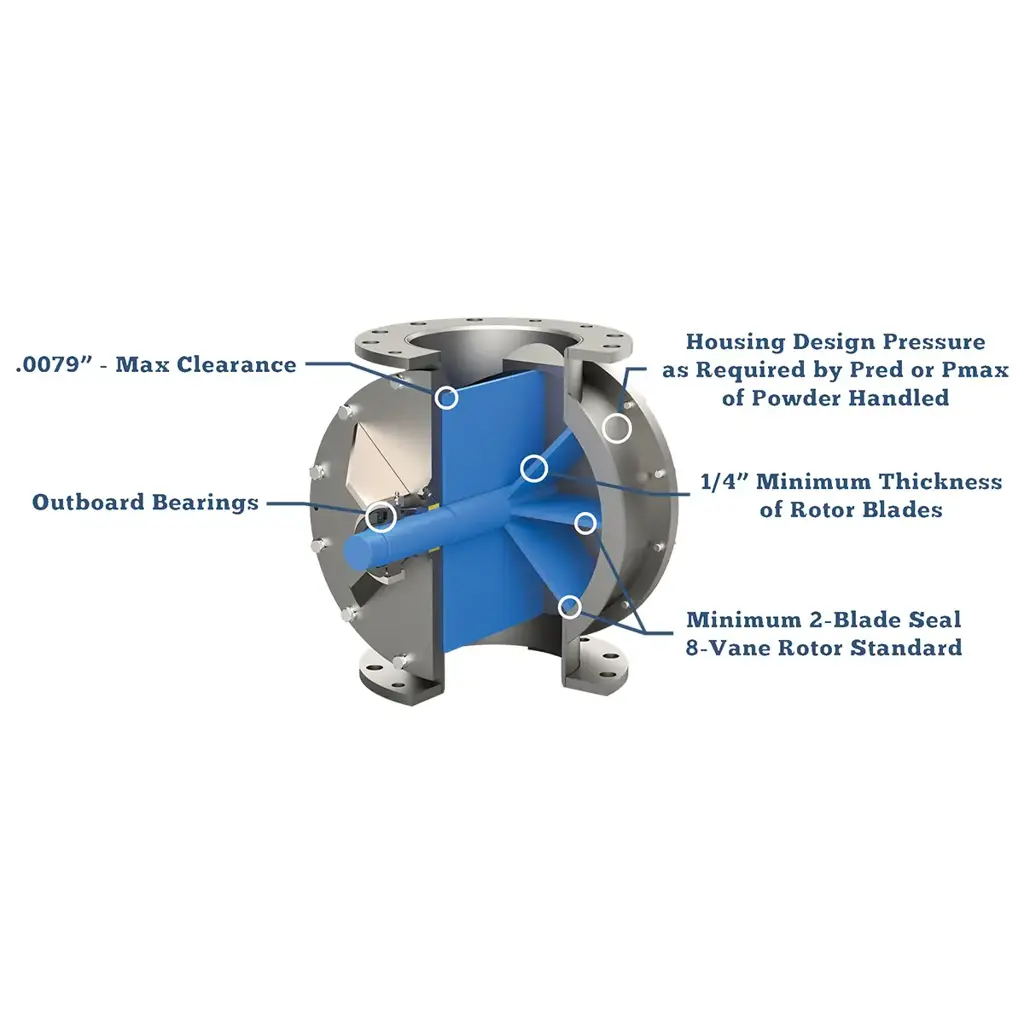

Our design process incorporates the unique Kst and Pmax values of your powder, ensuring the valve can withstand the maximum anticipated explosion pressure (Pred) in deflagration venting or suppression scenarios. For enclosures without such protection, we follow NFPA 69 standards for valve design.

Features & Options

Young Industries' NFPA-compliant rotary valves offer a range of features and options to ensure safe and efficient powder handling in your facility. These valves feature a close-clearance design to minimize dust accumulation and reduce the risk of deflagration propagation. Our team of expert application engineers work closely with you and your AHJ to ensure proper valve selection, installation, and compliance.

Our experienced application engineers work closely with you and your Authority Having Jurisdiction (AHJ) to ensure the equipment meets all necessary plant safety requirements. We hold both ASME U & UM certifications and can design and manufacture pressure containment rotary valves exceeding 15 PSIG when needed.

- Suitable for ST-1 and ST-2 dust classifications with a Pmax of 174 PSIG or less and are not intended for use with hybrid mixtures

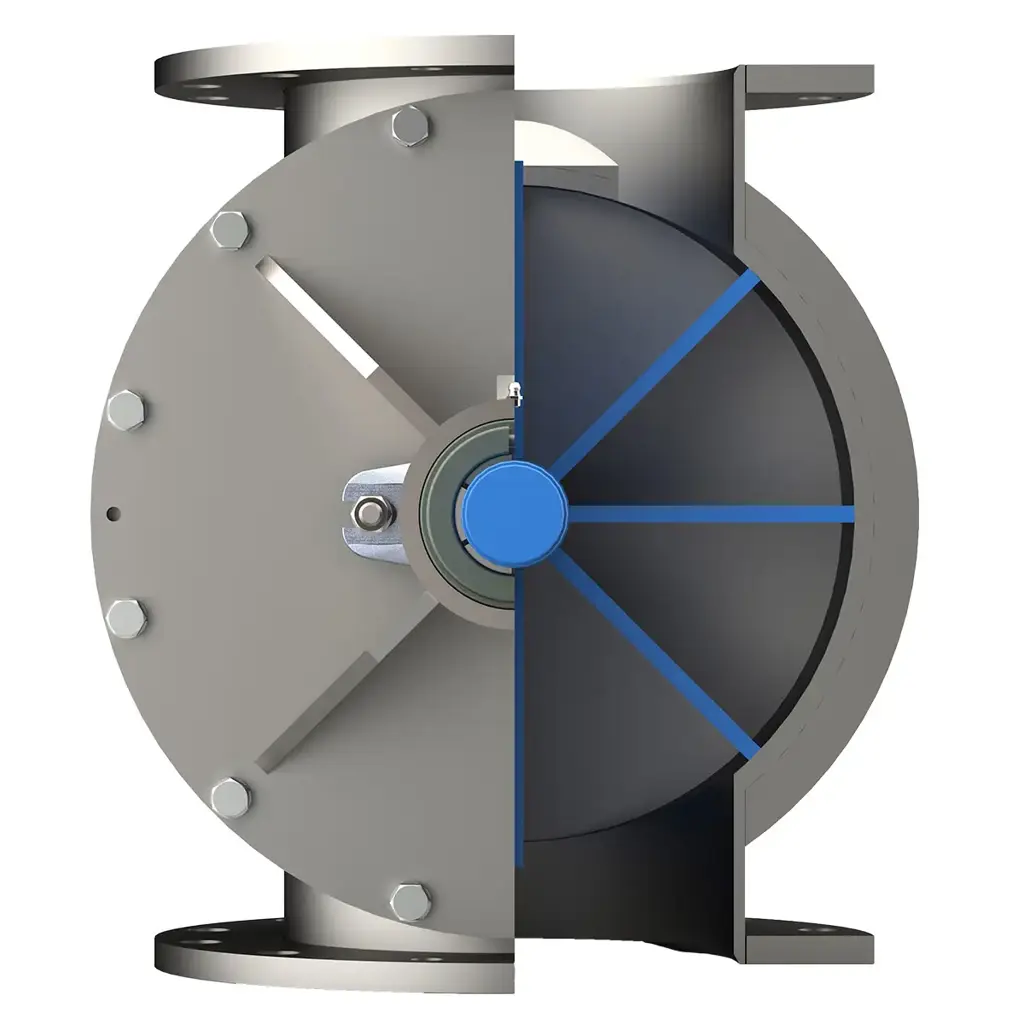

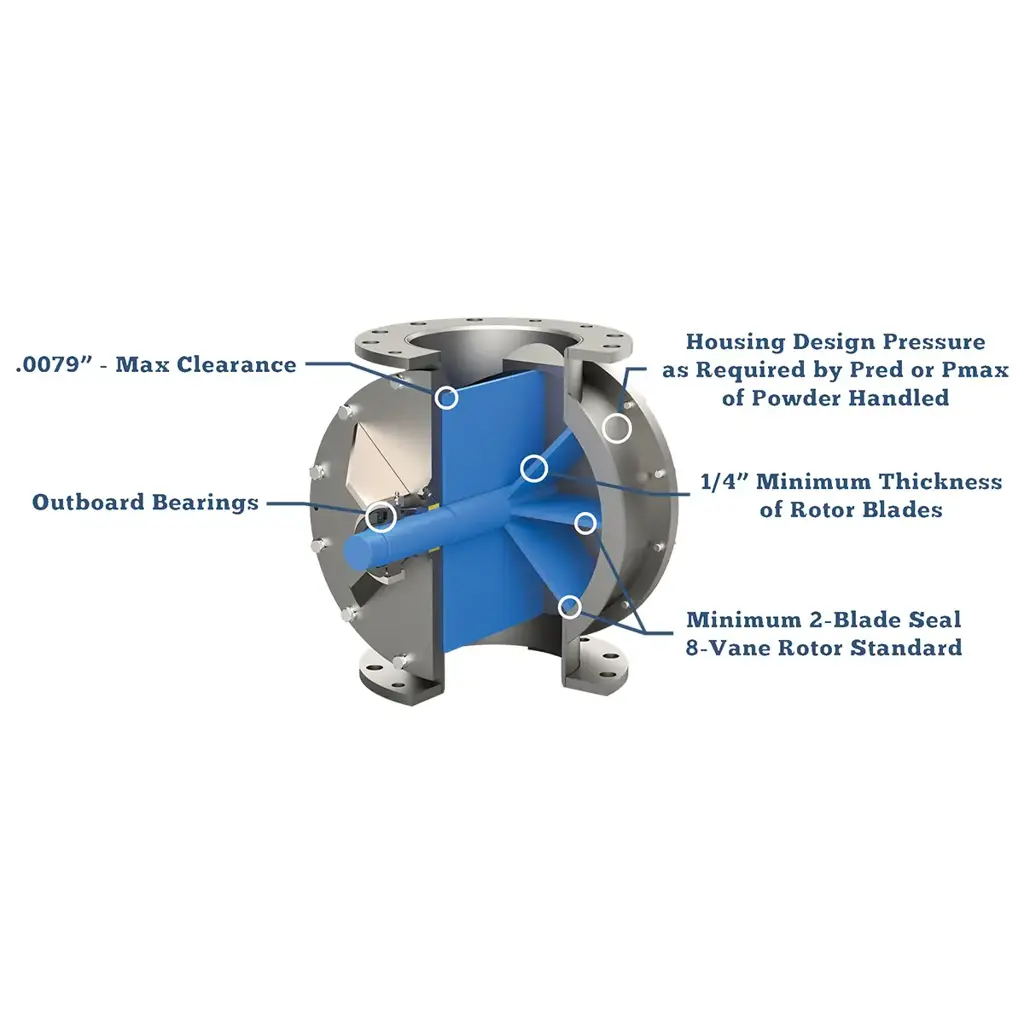

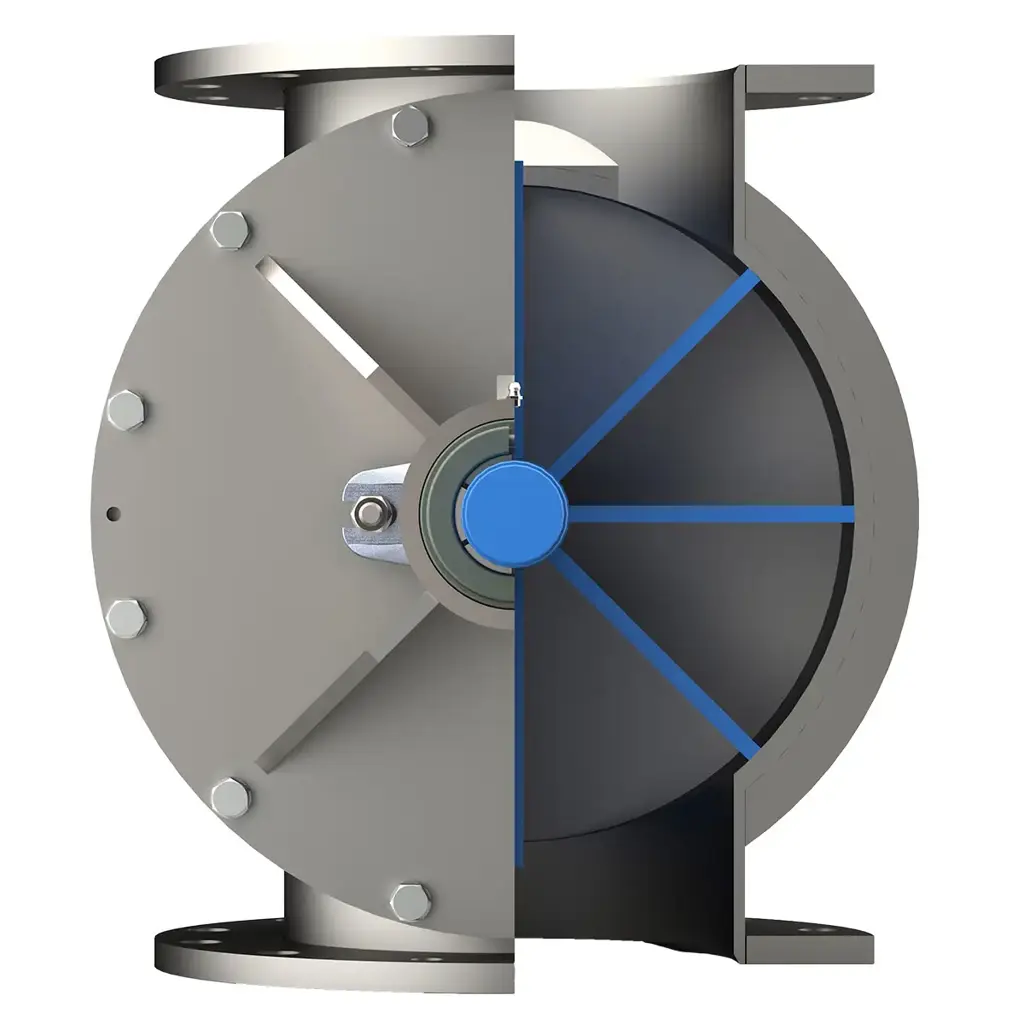

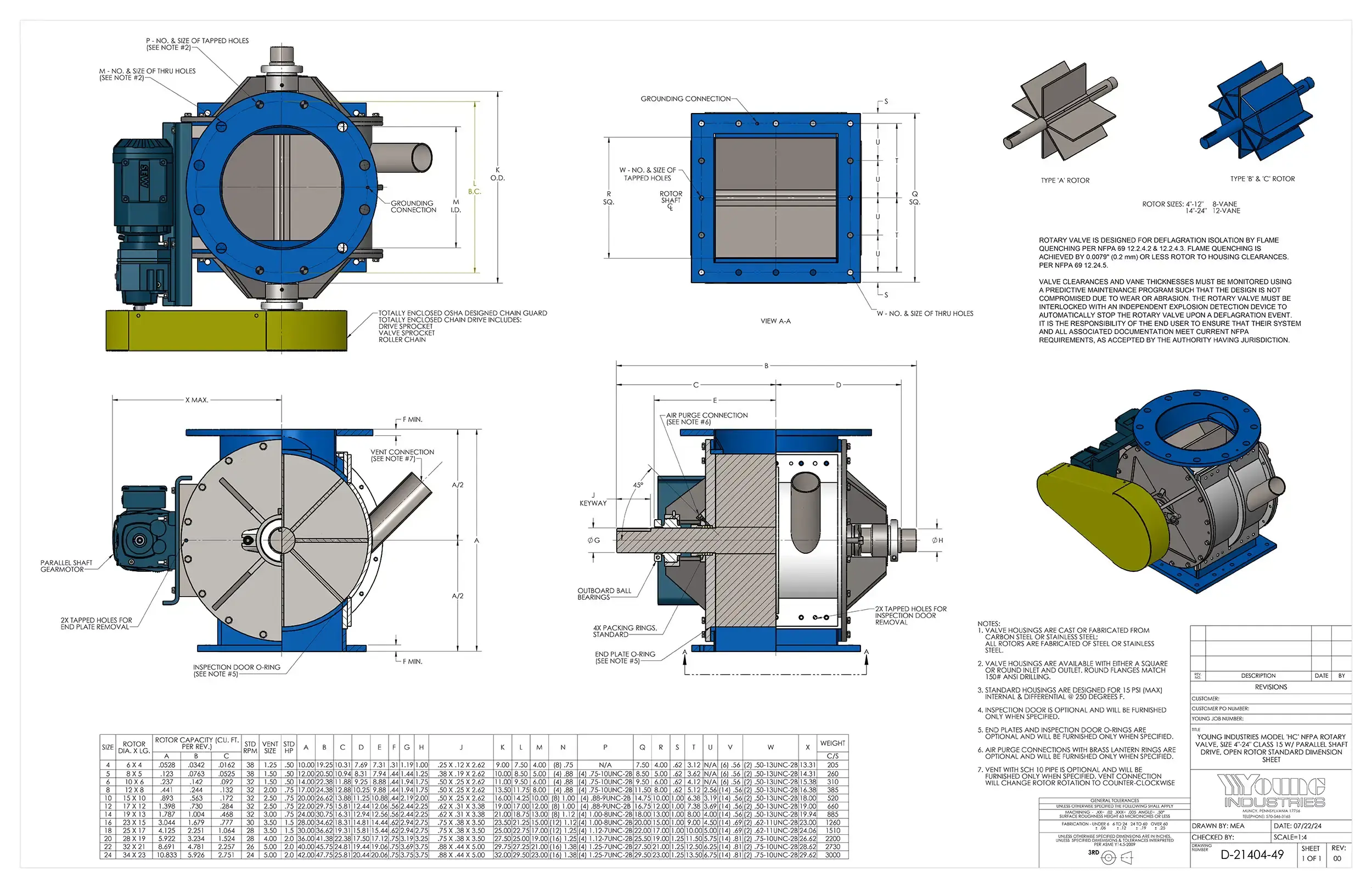

- Eight vane (minimum) open-end rotors

- Minimum two rotor blade seal on each side of housing

- Maximum clearances between the rotor and valve body is .0079"

- The rotor and housing are designed for the maximum anticipated explosion pressure as derived using NFPA 69 standards for the application requirement

- Outboard mounted bearings

- Fixed metal rotor tips with a minimum of 1/4" thickness

- PE certified calculations for pressure design of the rotary valve

- Hydrostatic pressure testing

- Replaceable rotor tips to allow for maintaining internal radial clearance

- Specially designed shrouded (closed end) rotors

Specifications

High Capacity NFPA Rotary Valves

| Size | Standard Speed (RPM) | Standard HP | Materials of Construction | Standard Design Temp. | Standard Design Pressure |

|---|---|---|---|---|---|

| 1 | * | 1/3 | Carbon Steel* Stainless Steel* Aluminum* Hastelloy^ Titanium^ |

250°F | 15 PSIG |

| 1-1/2 | * | ||||

| 2 | * | ||||

| 2-1/2 | * | ||||

| 3 | * | ||||

| 4 | 38 | 0.5 | |||

| 5 | |||||

| 6 | 32 | ||||

| 8 | 0.75 | ||||

| 10 | |||||

| 12 | |||||

| 14 | |||||

| 16 | 30 | 1.5 | |||

| 18 | 28 | ||||

| 20 | 2 | ||||

| 22 | 26 | ||||

| 24 | 24 |

Low Headroom NFPA Rotary Valves

| Size | Standard Speed (RPM) | Standard HP | Materials of Construction | Standard Design Temp | Standard Design Pressure |

|---|---|---|---|---|---|

| 4 | 38 | 0.5 | Carbon Steel* Stainless Steel* Aluminum* Hastelloy^ Titanium^ |

250°F | 15 PSIG |

| 5 | 38 | 0.5 | |||

| 6 | 32 | 0.5 | |||

| 8 | |||||

| 10 | |||||

| 12 | 0.75 | ||||

| 14 | 30 | ||||

| 16 | 1 | ||||

| 18 | 28 | ||||

| 20 | 1.5 | ||||

| 22 | 26 | ||||

| 24 | 24 |

*Cast or Fabricated

^Fabricated Only

Resources

Customization

When it comes to powder handling, safety is paramount. Our NFPA-compliant rotary valves are engineered to meet the most stringent industry standards and your unique process requirements. We offer a range of customization options to ensure your valve is perfectly suited to your application. From specific Kst and Pmax values to specialized materials and configurations, we'll work with you and your AHJ to design a valve that delivers both safety and performance.