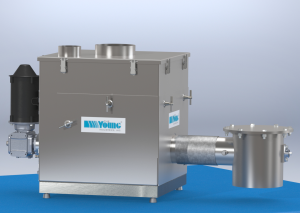

Description

- Compact, economical design combines feeder tube, support frame and hopper into one weldment

- Conveys materials without the high horsepower needs often found with other feeders

- Batch Accuracy up to +/- .1% typ. at 2 sigma

- Standard inlet to discharge lengths up to 60″

- Feed rates up to 800 cubic feet per hour

- Feeder Tube features Young Industries’ Patented STINGER® Screw Technology

- STINGER® Feed Hopper features a built in Young Industries SilentFlow Bin Discharger that conditions material without any moving parts or vibration

- Available in NEMA 4 or Explosion Proof designs

- Quick auger removal in minutes without the need for any tools

- Bearing housing includes a purged, double-lip shaft seal which separates material from bearings and provides maximum bearing life

- Young Industries STINGER® Feeder tube conditions material after it leaves the feed hopper

- STINGER® Feed Hopper features Young Industries SilentFlow Bin Discharger conditions material without any moving parts or vibration

Commonly Handled Materials

Adipic Acid – Carbon Black – Fly Ash – Metal Powders – Powdered Sugar – Aluminum Oxide – Ceramic Powders – Fumed Silica – Sodium Bicarbonate – Pigments – Antomite – Corn Flour – Iron Oxide – Powdered Minerals – Spices – Borax – Clays – Lime – Polymers – Titanium Dioxide (all grades)- Calcium Carbonate – Dextrose – Magnetite – Powdered Ceramics – Zinc Oxide

Feed Rates

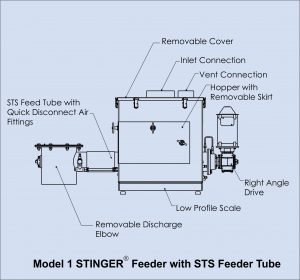

Feed Hopper

- Standard hopper capacities range from .3 to 30 cu. ft. (8.5 to 850 liters)

- Standard hopper sizes range from 12″ to 36″ square

- Removable covers available in painted carbon steel or stainless steel

Support Frame

- Skirt supported for compact low head room design

- Hanging mount frames are available as a special option

Scale Frame

Housing Construction

- Option 1: Painted Carbon Steel Exterior with bare metal interior

- Option 2: 304 Stainless Steel

- Option 3: 316 Stainless Steel

Standard Cover

- 18″ to 36″ diameter sizes: Removable cover

Constructed of light weight High Density Polyethelyne (HDPE)

Support Frame (If Required)

- Option 1: Painted Carbon Steel

- Option 2: 304 Stainless Steel

Feeder Tube:

- Standard: 304 Stainless Steel Housing with 316 Stainless TransFlow® Fluidizing Media

- Option 1: 316 Stainless Steel Housing with 316 Stainless Steel TransFlow® Fluidizing Media

Auger

- Option 1: Replaceable High Density Polyethelyne flighting on rigid 304 Stainless Steel Hex Shaft

- Option 2: 304 Stainless Steel

- Option 3: 316 Stainless Steel

Temperature Range

Scales are temperature compensated from 14º F to 104º F (10º C to 40º C)

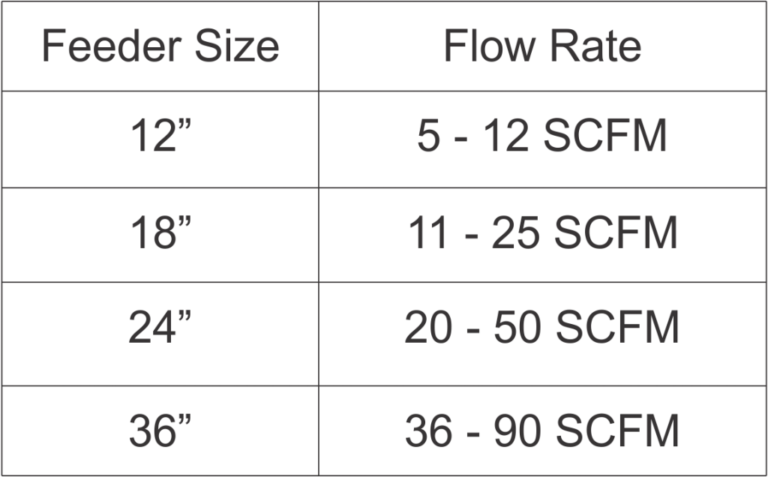

Compressed Air/Gas Usage

Feeder Controls

The Young Industries Model STS-2 Feeder is suitable for either Batch Feeding, Continuous Gravimetric Feeding, or Volumetric Feeding. The controls package set up determines the actual feeder package operation. Our family of Young Industries TOUCHSTONE controllers are designed to work seamlessly with each of our STINGER® Feeders. Customers may choose a suitable Batch, Continuous, or Volumetric control system to meet your specific application needs.

Standard TOUCHSTONE Features

- Ships pre-configured for quick setup

- NEMA 4 enclosure with optional upgrade to explosion proof enclosure

- Features Quick Disconnect Electrical Fittings for quick and easy maintenance

Electrical Area Classifications

- Standard NEMA 4

- Optional NEMA 4X

- Optional NEMA 7/9

Power Requirements

- TOUCHSTONE controls: Universal Input Voltage accepts 120-220 V/50-60hz, single phase electrical supply

- Instrument power: Standard 24V DC

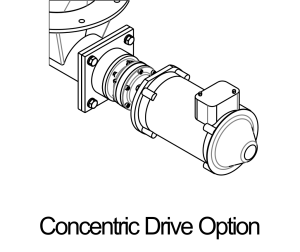

Feeder Drive

Motor:

- Option 1: 1/8 – 5 HP, 230/460 Volts,3 ph, 50 -60 Hz

- Option 2: 1/16 – 2 HP, 90 or 180 Volts, DC Motor

- Option 3: Stepper Motor, NEMA 4 or NEMA 7/9

** Explosion proof and wash down rated motors are also available as special options. Contact Young Industries for further information.

Gear Reducer Orientation

Standard Drawings

Videos

Warning

Some machines in this section are shown with guards or covers removed for the purpose of illustration. Machines must not be operated with guards, covers, or other protective devices removed or disabled.