Description

- Over 55 years of experience in applying rotary valve to bulk materials handling problems

- Design engineering expertise to reduce your total cost of ownership

- Longer service life by using high quality raw materials

- Built using the most modern manufacturing processes

- Industries lowest air or gas leakage through the valve

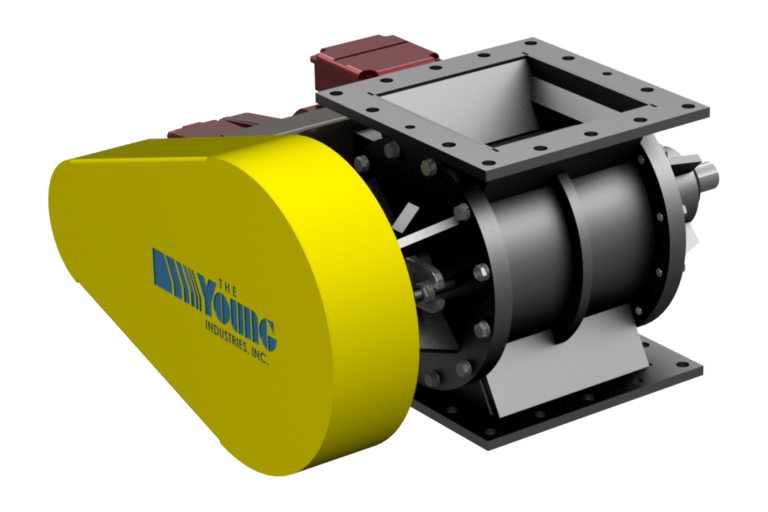

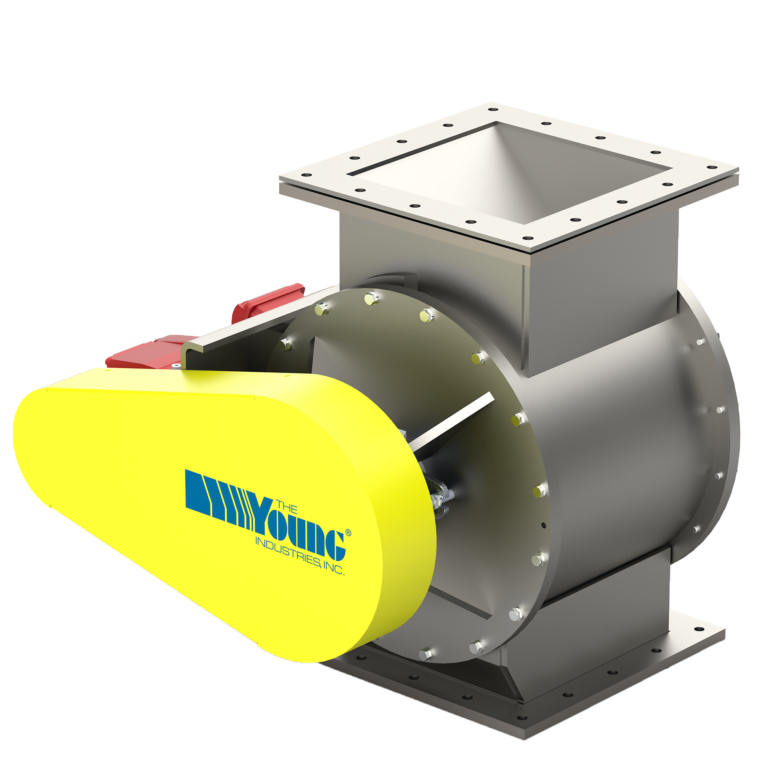

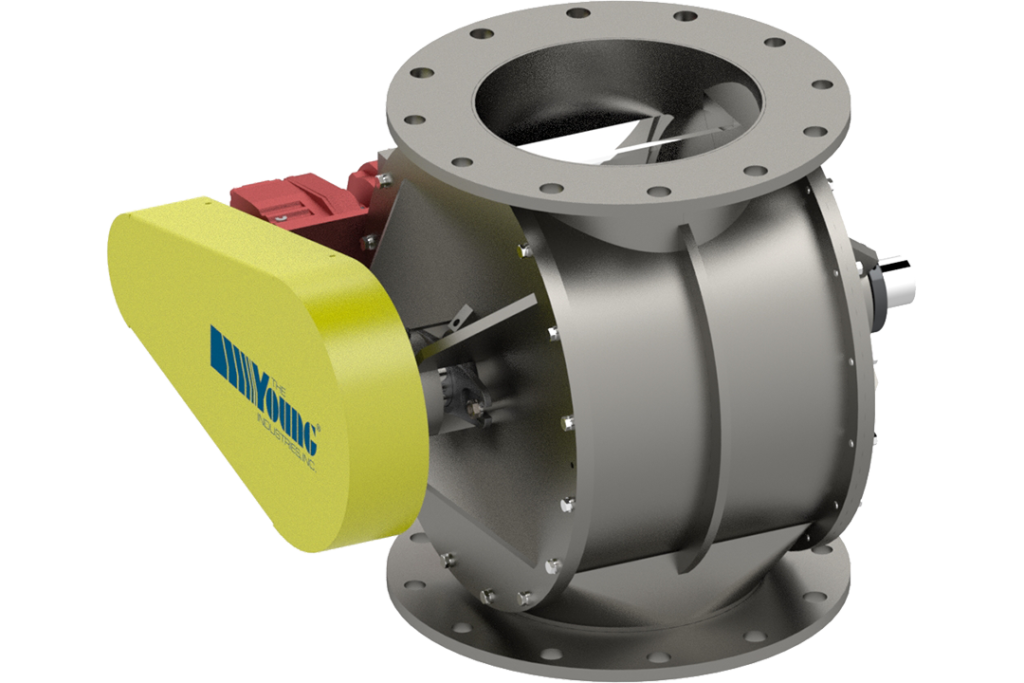

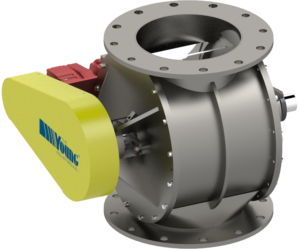

The Model “HC” Rotary Valve is used to prevent air or gas loss between two different pressure zones while allowing dry solids material to pass from one pressure zone to the other. The Model “HC” Rotary Valve is designed as airlocks and airlock feeder for handling 15 PSIG housing and differential pressure or vacuum.

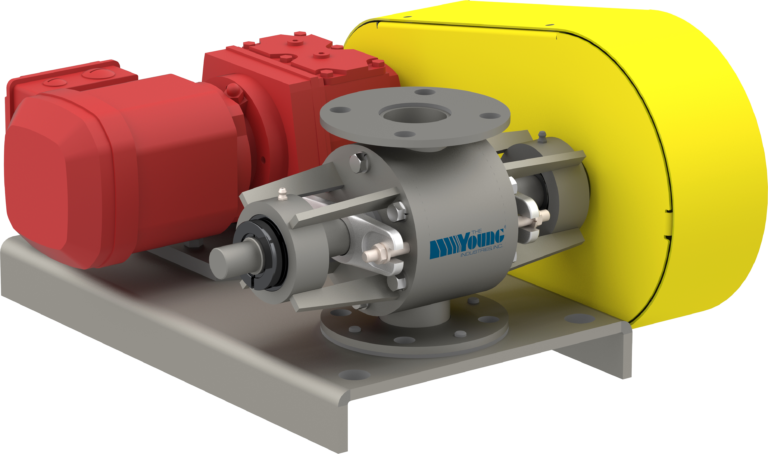

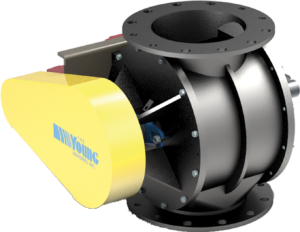

The Micro-Model HC Rotary Valves have vertical inlet and discharge throats. This two-blade seal with precision machined housing ensures there is minimum air or gas leakage in those applications where the valve is used to seal between two different pressure or vacuum zones. This series of Micro-Rotary Valves offer the standard features of the larger Model HC Rotary Valves and have many of the same optional features available.

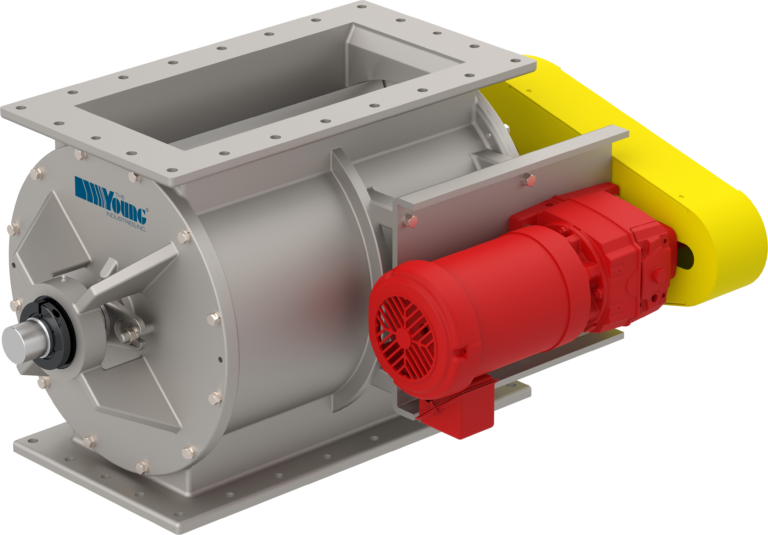

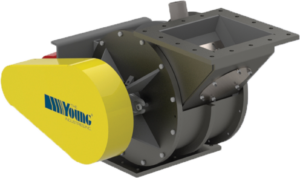

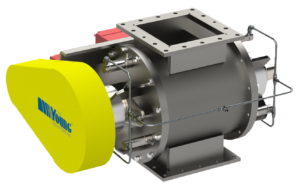

The Young Industries, Inc. Model “LH” (Low Headroom) Rotary Airlock Feeder Valve is a Drop-Thru Valve with a lower profile for applications requiring less headroom. The Model “LH” Rotary Airlock Feeder Valve is recommended when the valve is sized based matching a flange size and throughput capacity is not a concern. In addition to the low profile, the Model “LH” Rotary Valve low air or gas leakage.

Young Industries manufactures the Model LH, and Model HC Rotary Valves in Extended Lengths. The standard Model LH and Model HC Rotary Valves have Square flanged inlet and discharge connections. The extended length version for these rotary valves have rectangular flanged inlet and discharge connections.

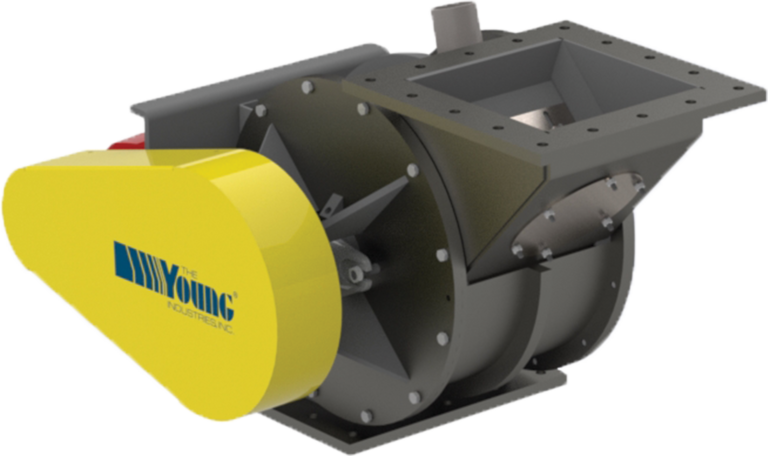

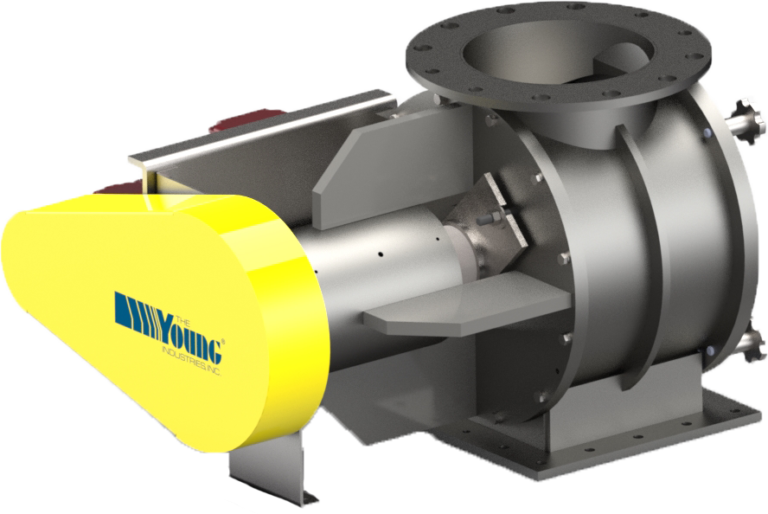

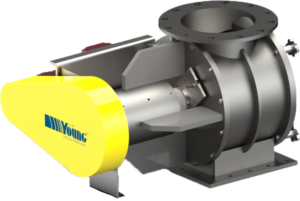

The Young Industries, Inc. Model “SE” (Side Entry) Rotary Valve is an Airlock Feeder Valve with an offset inlet. With this arrangement, the rotor pockets fill approximately 40% which prevents the pellets or chips from clipping or jamming the valve. The Model “SE” valve is recommended when material needs to be metered from a silo or hopper having a head of material above the outlet.

The Young Industries, Inc. Model RNHC Rotary Valve is a straight drop-thru valve specifically designed for metering pelletized or prill materials with particle sizes 1/16” to 1/4”. In many applications, this valve is used for variable speed and rate control. This is a vertical drop through rotary valve with a pellet-flow inlet throat and rotor that minimizes clipping of the pellets as they enter the rotor pockets.

The Young Industries, Inc. Model “BT” (Blow-Thru) Rotary Airlock Valve is a drop-thru valve with a convey line built into the bottom of the end plates. This Rotary Valve is used to meter sticky or cohesive powder bulk materials in a pneumatic conveyor. The conveying air blow through the valve’s rotor pockets to assist the material’s discharge.

The Quick Clean Rotary Valve is available as the Model QC and Model CA styles. The Model QC and Model CA Quick Clean Rotary Valves are constructed using Young Industries Model LH or HC Drop-thru Rotary Valve housings, or the Model SE Side Entry Valve housings.

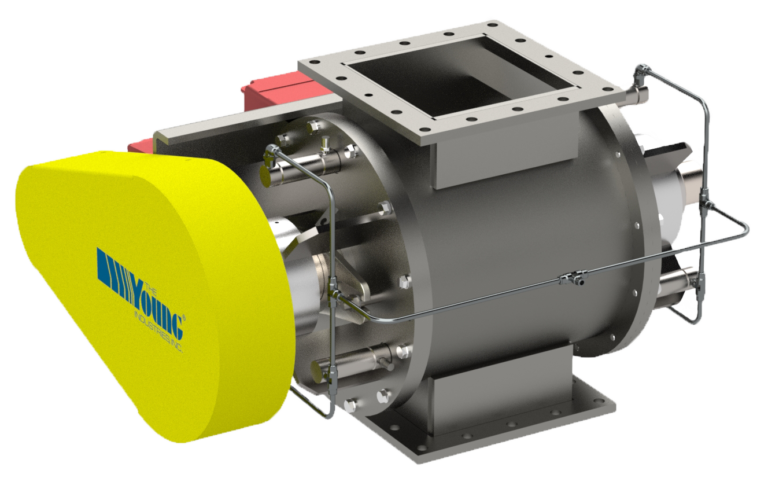

The Young Industries, Inc. Model “ES” (End Seal) Rotary Valve is a Drop-Thru-Airlock Feeder Valve, either a “HC” (High Capacity) or “LH” (Low Headroom) or “SE” (Side Entry) model with peripheral sealing rings that press against the rotor shroud to reduce leakage through the valve.

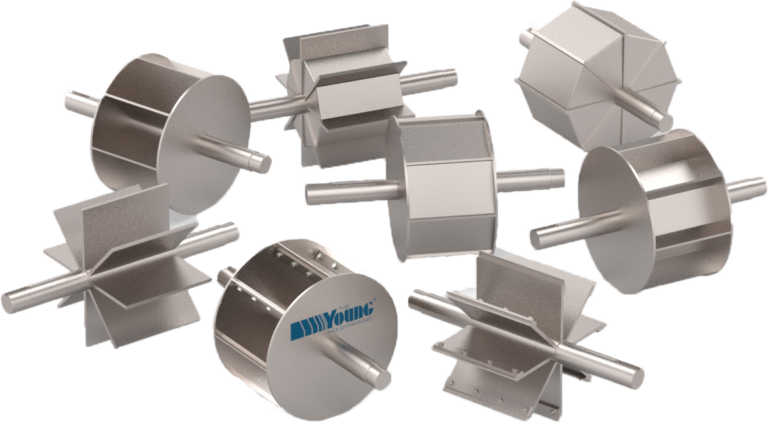

Several of our rotor types are offered in two different designs. They are the open-end and closed-end (shrouded) rotor designs. With the open-end design, the blades are welded directly to the rotor shaft. With the closed-end (shrouded) design there are additional discs welded to the shaft and blade ends. Each design has application advantages and disadvantages. Explore the various rotor types we offer below.